Ensuring Durability and Reliability: Load Testing at O&Y Precision

At O&Y Precision, the reliability and durability of every part we produce are paramount. Load testing plays a crucial role in our quality assurance process, allowing us to evaluate the performance of parts under real-world stresses and strains. By utilizing advanced load testing machines and following rigorous testing protocols, we ensure that each component meets the highest standards of safety and quality. Our skilled technicians meticulously monitor each test, providing customized solutions tailored to specific project requirements. Trust O&Y Precision for components that deliver exceptional performance and reliability.

Precision and Innovation: How Our Machine Shop Excels in Aerospace, Medical, and Semiconductor Manufacturing

At O&Y Precision , we specialize in providing high-precision machining solutions for the aerospace, medical, and semiconductor industries. With expertise in 5-axis machining and the ability to work with a diverse range of materials, we ensure quality and accuracy in every project. Discover how our innovative approach and rigorous inspection processes set us apart in delivering exceptional machining services.

How to Become a CNC Machinist and a Master Programmer: A Journey with O&Y Precision

Embark on a rewarding career as a CNC machinist and master programmer with O&Y Precision. Our comprehensive training programs, cutting-edge technology, and personalized development plans ensure you excel in both machining and programming. Join us to become a leader in the industry and master the art of precision machining.

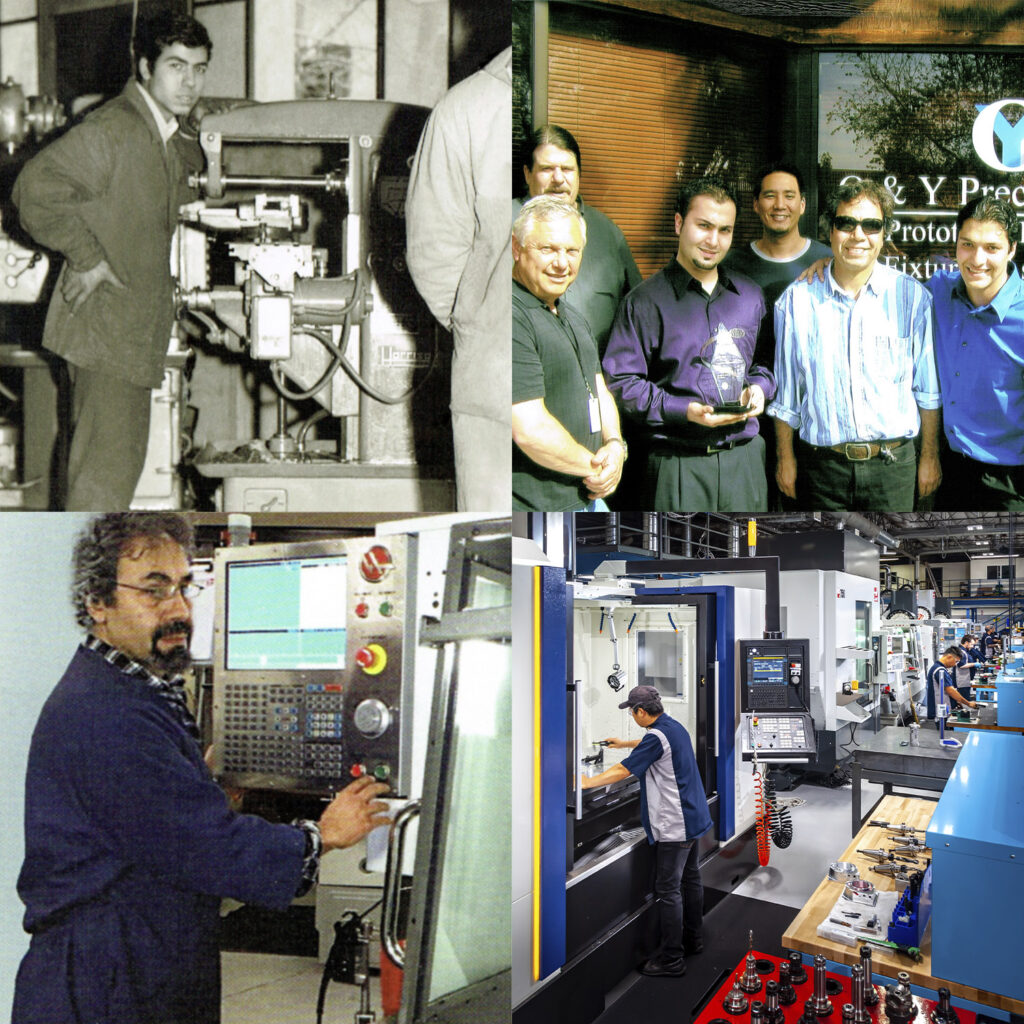

The Heartbeat of O&Y Precision: Our Dedicated Team

O&Y Precision, Inc. was founded in 2002 by Maximum Oyar and his two sons. Our success in precision manufacturing is driven by our dedicated employees, whose skills and loyalty form the backbone of our operations. Learn more about our journey and the team that makes it all possible.

How to Leverage LinkedIn to Grow Your Machine Shop Business

Leveraging LinkedIn to grow your machine shop business is an effective strategy to attract new customers, build brand awareness, and showcase your expertise. With over 900 million professionals on LinkedIn, it’s a prime platform for B2B marketing. Start by optimizing your company page with detailed information and high-quality visuals. Post a mix of thought leadership articles, customer testimonials, and behind-the-scenes videos to engage your audience. Join industry groups and actively participate in discussions to build relationships and establish your expertise. Utilize LinkedIn’s features like ads and analytics to refine your strategy and maximize your reach. By consistently providing valuable content and engaging with your network, you can significantly enhance your machine shop’s visibility and credibility on LinkedIn.

Mastering Machining: A Guide to Selecting the Right Endmills for Every Material and Application

Explore the essentials of selecting the right endmills for your machining needs. Learn about different types, coatings, and how to optimize feeds and speeds for various materials, with practical examples and case studies from the industry

Elevating Aerospace Defense: The Excellence of O&Y Precision Machine Shop

In the dynamic realm of aerospace defense, precision, reliability, and expertise are paramount. Among the myriad of options available, O&Y Precision Machine Shop stands out as a beacon of excellence, offering unparalleled services tailored specifically to the rigorous demands of the aerospace industry. With a steadfast commitment to quality, innovation, and adherence to ISO 9100 standards, O&Y has emerged as a trusted partner for organizations seeking superior solutions in aerospace machining.

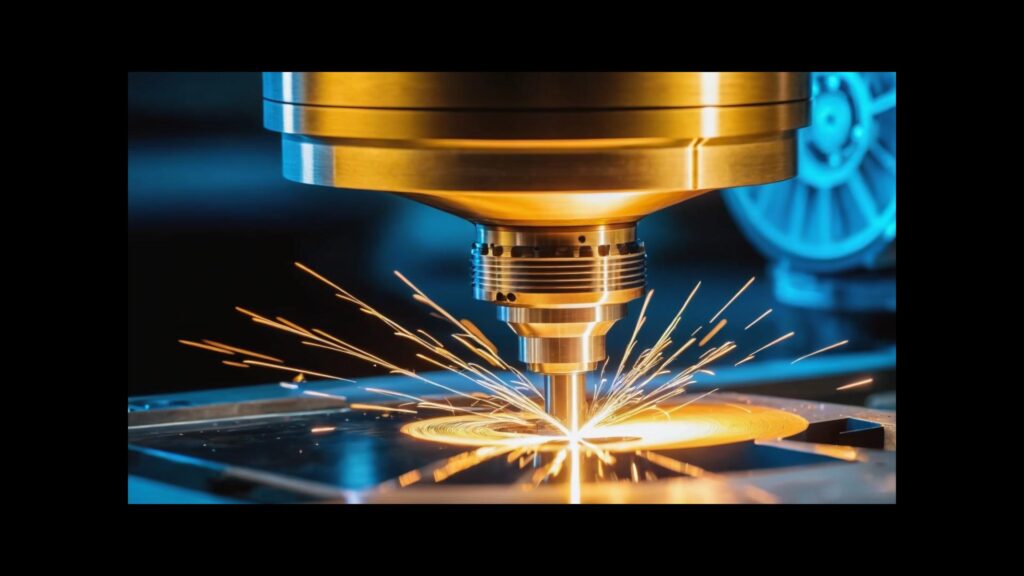

Title: Mastering CNC Manufacturing: The Crucial Elements for High-Quality Parts

Discover the epitome of precision with our CNC manufacturing services. From expert setup to advanced programming and meticulous material knowledge, we craft high-quality parts with unrivaled accuracy. Experience excellence in CNC machining today.

Unlocking the Future of Aerospace Manufacturing: Innovative Solutions and Technologies

At O&Y Precision, we recognize that the key to our success lies in our ability to efficiently and accurately machine exotic high nickel alloys. These materials, known for their exceptional strength and resistance to extreme environments, pose unique challenges in machining due to their hardness and thermal properties. Our approach to overcoming these challenges is twofold: leveraging state-of-the-art equipment and fostering a culture of innovation among our skilled engineers and technicians.

Our facility is equipped with the latest in 5-axis machining technology, allowing for unparalleled precision in crafting complex aerospace components. This advanced equipment, combined with our team’s deep understanding of material properties, enables us to execute intricate designs that meet the rigorous standards of the aerospace industry.

Innovation is at the heart of our process. We continuously explore new machining techniques and tooling solutions to enhance our efficiency and output quality. Through rigorous testing and adaptation, we develop optimized processes that not only meet but exceed our clients’ expectations for precision and reliability.

Our commitment to excellence extends beyond our machining capabilities. We prioritize continuous improvement and adhere to strict quality control measures to ensure that every component we produce is of the highest standard. By integrating these principles into our approach to machining exotic materials, O&Y Precision stands as a beacon of reliability and innovation in the aerospace sector.

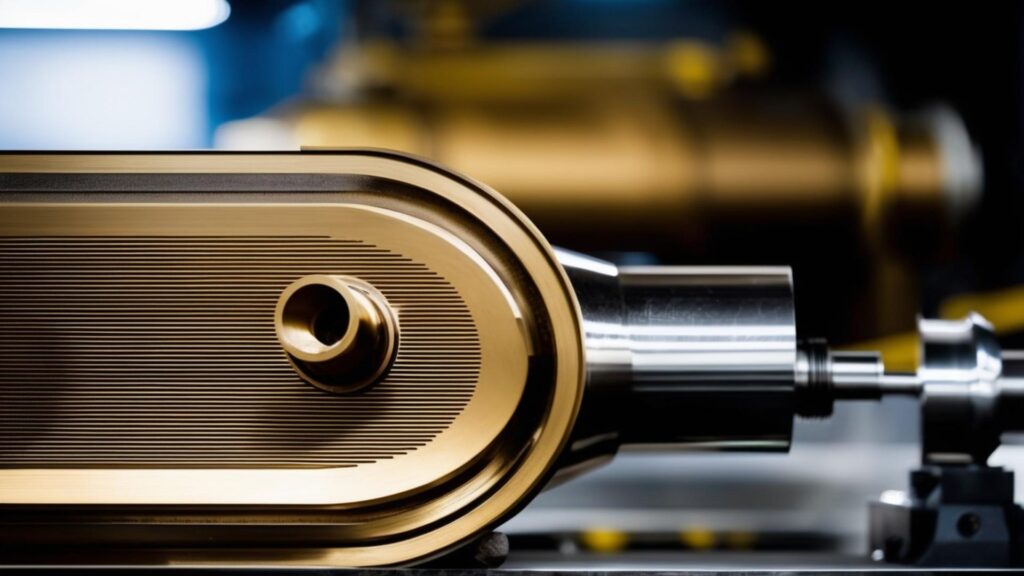

Precision Perfected: The Artistry of Machine-Surfaced Parts

Protecting machined surface parts from scratches is crucial for ensuring their optimal performance and longevity. By implementing meticulous handling procedures, utilizing protective packaging, and maintaining controlled environmental conditions, manufacturers can preserve the flawless finish of these critical components. Learn how to safeguard your machined parts and uphold the highest standards of quality in industrial settings.

Is it important to design your machining project with the final part finish in mind?

Surface finish dictates your final part’s external surface quality, dimensional accuracy, durability, and overall appearance. It is crucial to design your part and select your machining process with your final finish in mind. Machining processes such as milling, turning, and drilling often leave behind tool marks and rough surfaces that will need to be addressed,…

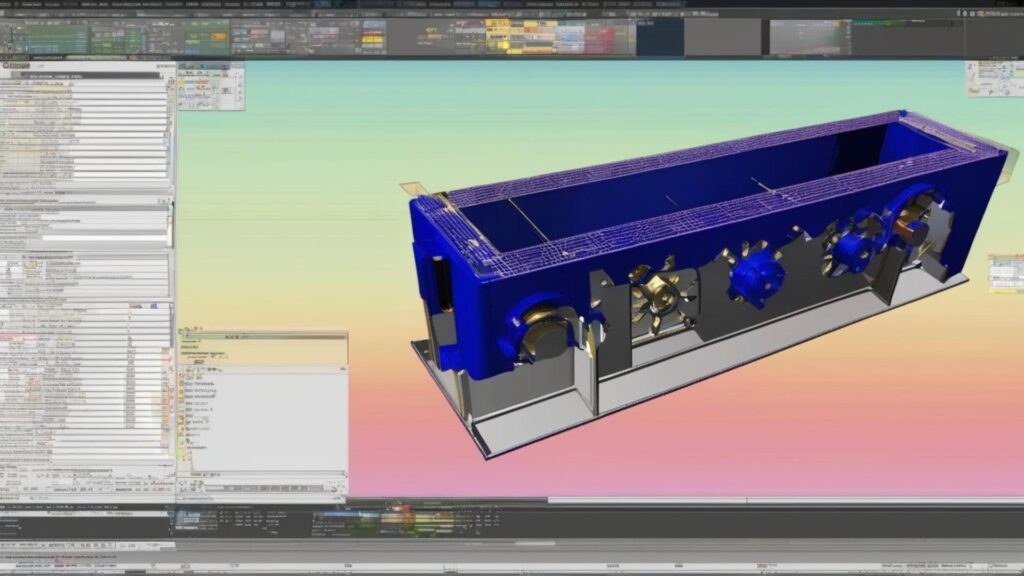

From Design to Reality: How CAD/CAM Software Revolutionizes Machining

In the dynamic world of modern manufacturing, CAD/CAM software stands as the cornerstone of precision and efficiency. This powerful duo, comprising Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM), revolutionizes the way components are designed, fabricated, and brought to life.

CAD software serves as the digital canvas where designers and engineers translate their ideas into precise blueprints. With intuitive tools and sophisticated features, intricate geometries and complex structures are crafted with ease, ensuring every detail is meticulously captured. From concept to design iteration, CAD empowers creators to visualize, refine, and perfect their creations before they materialize into physical form.

Mastering Precision: A Guide to Choosing the Right Endmill for Every Job

Endmills are cutting tools used in milling applications, and they come in a variety of types and configurations. The choice of endmill depends on the specific machining operation, the material being machined, and the desired outcome. Here are some common types of endmills and their applications in machine shops: Flat Endmill: Application:…

cleanroom assembly

Step into the world of cleanroom assembly, where the pursuit of perfection unfolds in a meticulously controlled environment. Within these sterile walls, the air is pure, the surfaces pristine, and every particle is treated as a potential disruptor to the delicate dance of precision manufacturing.

Imagine a symphony of technology and human expertise, where workers don superhero-like attire and machines act as guardians against invisible adversaries. In this ballet of cleanliness, the assembly process is not merely a task but a choreographed masterpiece.

Discover the significance of particle control through the lens of specialized machines like HEPA filters and Laminar Flow Hoods, each playing a crucial role in crafting flawless products. It’s not just about assembly; it’s a commitment to excellence, where every move contributes to the creation of products that stand as testaments to the highest standards in manufacturing.

Explore the artistry of cleanroom assembly, where every detail matters, and precision reigns supreme.

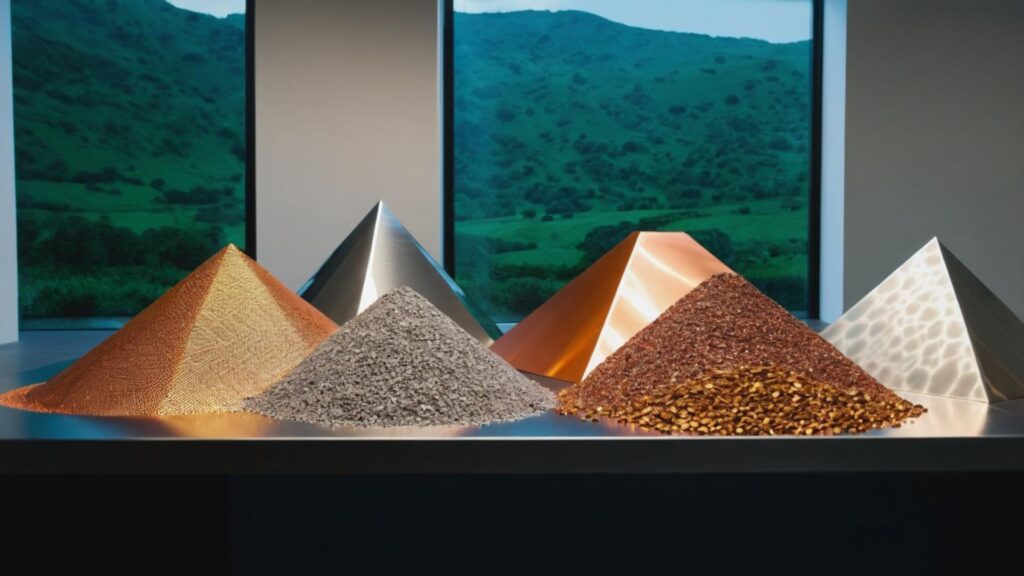

Precision Engineering in Exotic Realms: Advanced CNC Machining of High-Performance Metals

CNC machining of exotic metals involves using Computer Numerical Control (CNC) machines to cut, shape, and form metals that are considered exotic due to their unique properties, high cost, or challenging machinability. Exotic metals often have superior characteristics such as high strength, corrosion resistance, and heat resistance, making them suitable for specialized applications in industries…