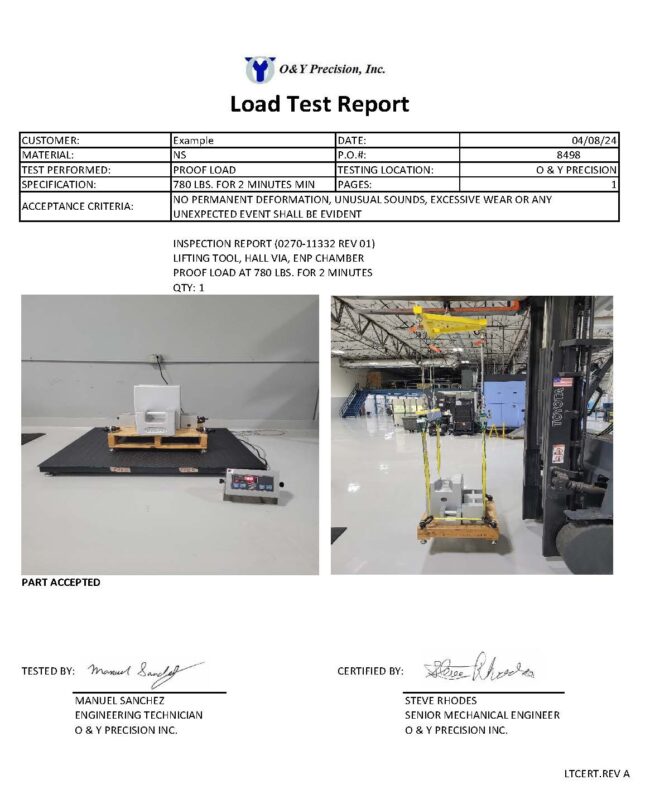

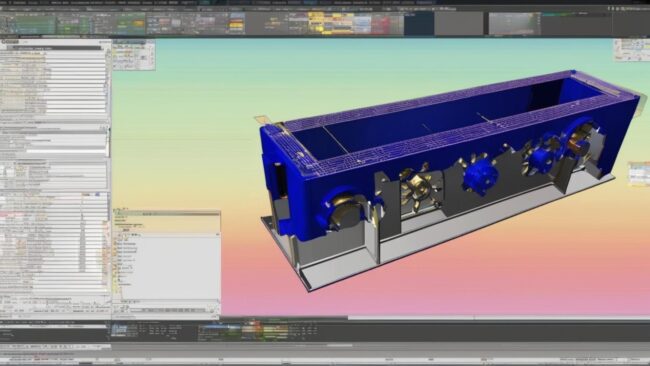

Precision Inspection & Quality Assurance

At OY Precision, inspection is more than a process — it’s our promise. Using Zeiss CMMs and ISO 9001:2015-certified systems, we deliver precision-verified, tight-tolerance parts for aerospace, medical, defense, and industrial applications. From first-article to final inspection, we ensure every component meets exact specifications — with full traceability and zero compromise.