Introduction: At O&Y Precision, we understand that the reliability and durability of every part we produce are paramount. This is why we place a significant emphasis on load testing as part of our quality assurance process. In this blog post, we’ll delve into what load testing is, its importance, and how O&Y Precision ensures that each part meets the highest standards through rigorous load testing procedures.

What is Load Testing? Load testing is a critical process used to evaluate the performance of a part under specific conditions. By applying various loads, we can assess how a part will behave under real-world stresses and strains. This testing helps us determine the maximum load a part can handle before it deforms or fails, ensuring it can perform reliably in its intended application.

The Importance of Load Testing:

- Ensuring Safety:

- Load testing is essential for ensuring the safety of components used in critical applications. Whether it’s parts for aerospace, automotive, or industrial machinery, knowing that each piece can withstand operational stresses is crucial.

- Quality Assurance:

- Through load testing, we can verify that our manufacturing processes produce parts that meet stringent quality standards. This testing helps us identify any potential defects or weaknesses before the parts are delivered to our clients.

- Customer Confidence:

- By consistently delivering parts that have been rigorously tested, we build trust and confidence with our customers. They can rely on O&Y Precision for components that not only meet but exceed their expectations.

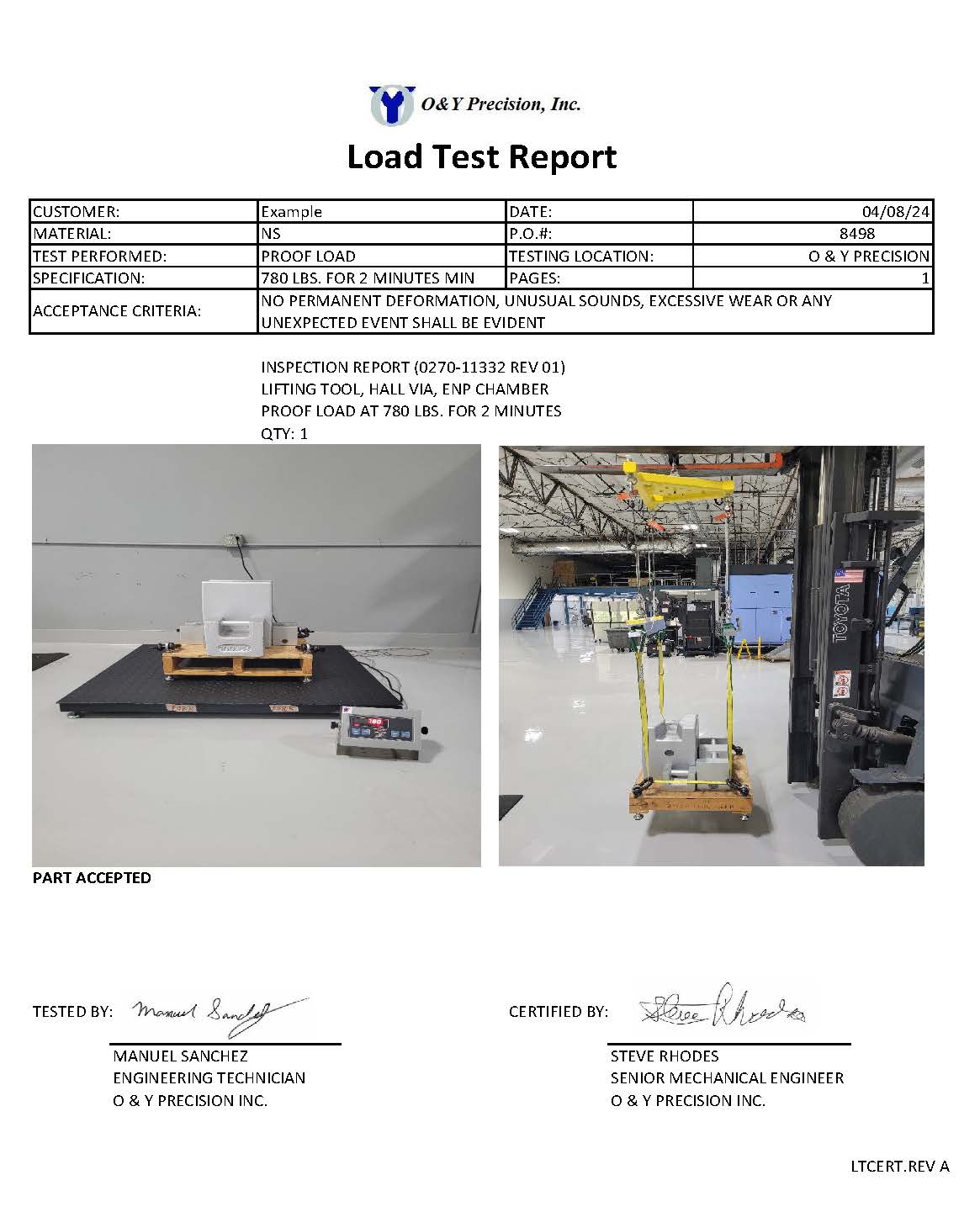

O&Y Precision’s Load Testing Capabilities:

- State-of-the-Art Equipment:

- At O&Y Precision, we use advanced load testing machines that can apply precise loads to parts of varying sizes and materials. Our equipment is capable of simulating a wide range of real-world conditions, ensuring comprehensive testing.

- Experienced Technicians:

- Our team of skilled technicians has extensive experience in load testing. They meticulously set up and monitor each test, ensuring accurate and reliable results. Their expertise allows us to interpret test data effectively and make informed decisions about part performance.

- Comprehensive Testing Procedures:

- We follow rigorous testing protocols to ensure consistency and reliability. Each part undergoes a series of tests, including static and dynamic load testing, to assess its performance under different conditions. This thorough approach helps us identify any potential issues early in the process.

- Customized Testing Solutions:

- Recognizing that each project has unique requirements, we offer customized load testing solutions tailored to specific needs. Whether it’s high-cycle fatigue testing for automotive parts or high-load testing for industrial components, we can adapt our processes to meet the demands of any project.

Case Study: Success in Load Testing: One of our recent projects involved load testing components for a leading aerospace manufacturer. The parts required to meet strict safety and performance standards. Through our comprehensive load testing procedures, we identified potential areas for improvement and optimized the design to enhance durability. The result was a set of components that exceeded the client’s expectations and performed flawlessly in the field.

Conclusion: At O&Y Precision, load testing is more than just a step in our manufacturing process; it’s a commitment to quality, safety, and customer satisfaction. By leveraging advanced equipment, experienced technicians, and customized solutions, we ensure that every part we produce can withstand the demands of its intended application. Trust O&Y Precision for components that deliver exceptional performance and reliability.

Call to Action: To learn more about our load testing capabilities and how we can assist with your next project, please contact us at Robbie@oyprecision.com. Let O&Y Precision be your partner in precision manufacturing and quality assurance.