Honoring the Craft: The Enduring Value of Manual Machining in a CNC-Driven World

In today’s fast-paced manufacturing environment, CNC (Computer Numerical Control) machines have revolutionized the way we produce parts, offering unmatched precision, speed, and efficiency. However, in our rush to embrace this technology, we often overlook the roots of machining: the manual processes that laid the foundation for everything we do today. It’s essential to recognize the value of traditional manual machining and the old-school machinists who continue to keep this craft alive. Their skills remain indispensable in an industry increasingly dominated by automation.

The Relevance of Manual Machining in a CNC World

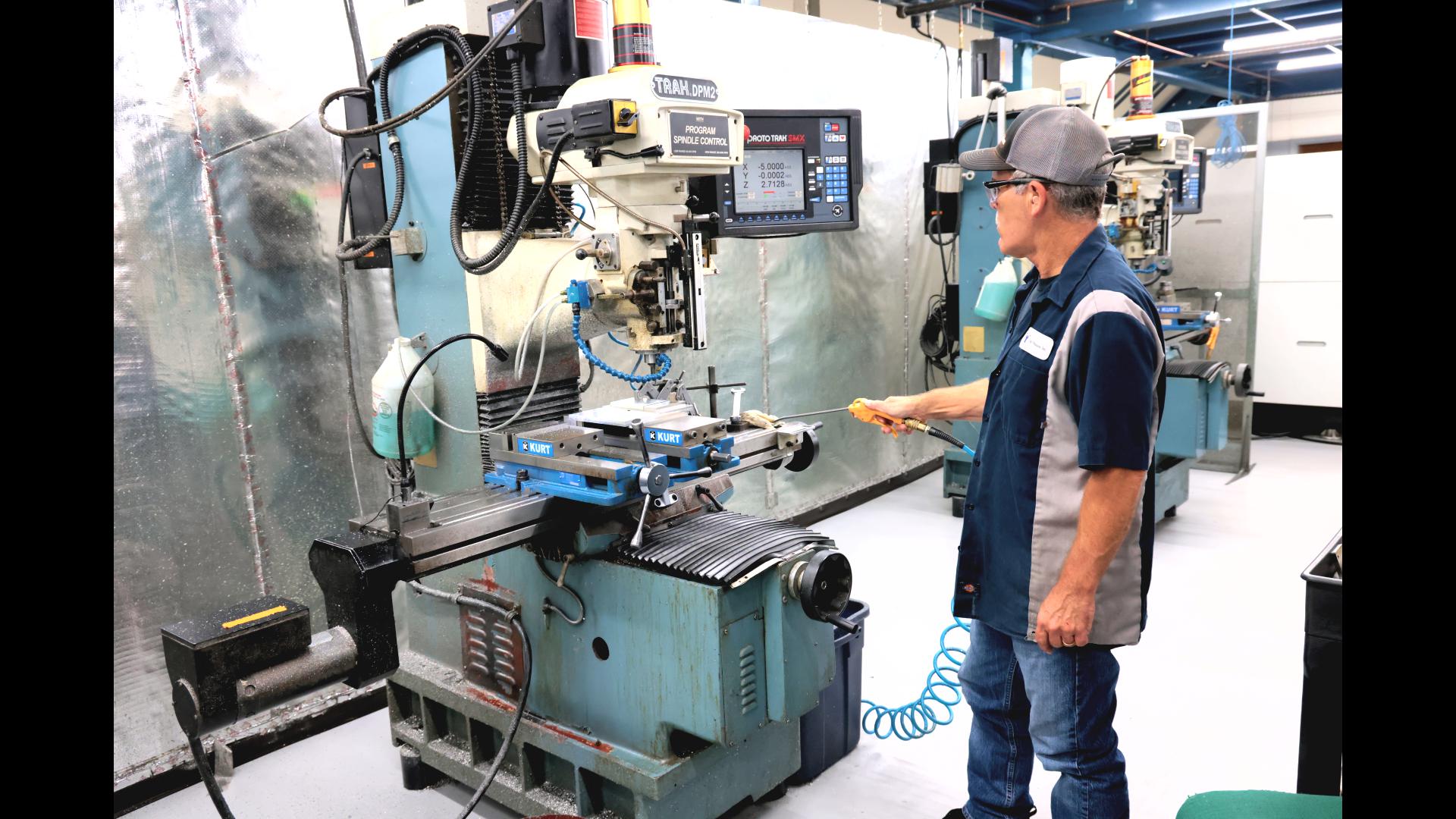

Manual machining, though less common in large-scale production, still holds significant relevance in the modern machine shop. For tasks that require a high degree of flexibility, custom work, or one-off parts, manual machines are often the preferred choice. Unlike CNC machines, which require programming and setup time, manual machines allow machinists to make immediate adjustments and modifications. This makes them ideal for quick-turnaround jobs, small production runs, and repairs, where speed and adaptability are crucial(

Moreover, manual machines are often more cost-effective for smaller operations. The initial investment and maintenance costs are lower than those of CNC machines, making manual machining a practical choice for shops operating on tighter budgets. Additionally, the absence of complex programming requirements means that manual machining can be faster for simpler tasks, further enhancing its utility in certain situation

The Unique Skills of Old-School Machinists

The machinists who honed their skills on manual lathes, mills, and grinders possess a depth of knowledge that goes beyond what can be programmed into a CNC machine. These craftsmen rely on their senses—sight, sound, and touch—to guide them through the machining process, making real-time adjustments based on their intimate understanding of the machine and material. This ability to “feel” the work is something that no amount of CNC programming can replicate(

Old-school machinists are not just operators; they are problem solvers and innovators. They can adapt to unexpected challenges, such as material inconsistencies or complex geometries, with a level of dexterity and intuition that is born from years of hands-on experience. This expertise is particularly valuable when working with custom parts or when precision is critical(

Complementing CNC Technology with Manual Machining

Rather than viewing manual and CNC machining as competing technologies, it’s more accurate to see them as complementary. In a well-rounded machine shop, having both capabilities ensures that you can tackle a broader range of projects efficiently. While CNC machines handle large-scale, repetitive tasks with high precision, manual machines excel in areas where flexibility and quick decision-making are needed(

For instance, when a CNC machine is tied up with a long production run, a manual machine can be used to complete smaller jobs without interrupting the workflow. This dual capability not only maximizes efficiency but also allows a shop to be more responsive to customer needs. It’s this blend of technology and traditional craftsmanship that gives a shop a competitive edge(

Learning from the Masters: Lessons for Modern Machinists

Today’s machinists can learn a great deal from those who have mastered manual machining. Understanding the fundamentals of manual machining provides a strong foundation for operating CNC machines. It fosters a deeper appreciation for the art of machining and develops critical problem-solving skills that are essential in maintaining the high standards of modern manufacturing(

Training programs that include manual machining techniques alongside CNC instruction produce well-rounded machinists who are better prepared to handle the diverse challenges of the industry. By integrating these traditional skills into modern training, we ensure that the legacy of manual machining continues to thrive, even as technology advances

Honoring the Legacy of Manual Machining

Recognizing the contributions of manual machinists isn’t just about honoring the past; it’s about preserving a set of skills that remain vital to the industry’s future. These machinists possess a wealth of knowledge that is invaluable for training the next generation, ensuring that the art of machining remains both innovative and deeply rooted in its rich history.

As we continue to push the boundaries of what’s possible with CNC technology, let’s not forget where it all started. The manual machines, and the craftsmen who operate them, deserve our respect and recognition. Without them, many of the intricate, custom, and high-quality parts that are essential to today’s world would simply not be possible.