Why Investing in a Zeiss CMM is a Game Changer for Precision Manufacturing

Introduction

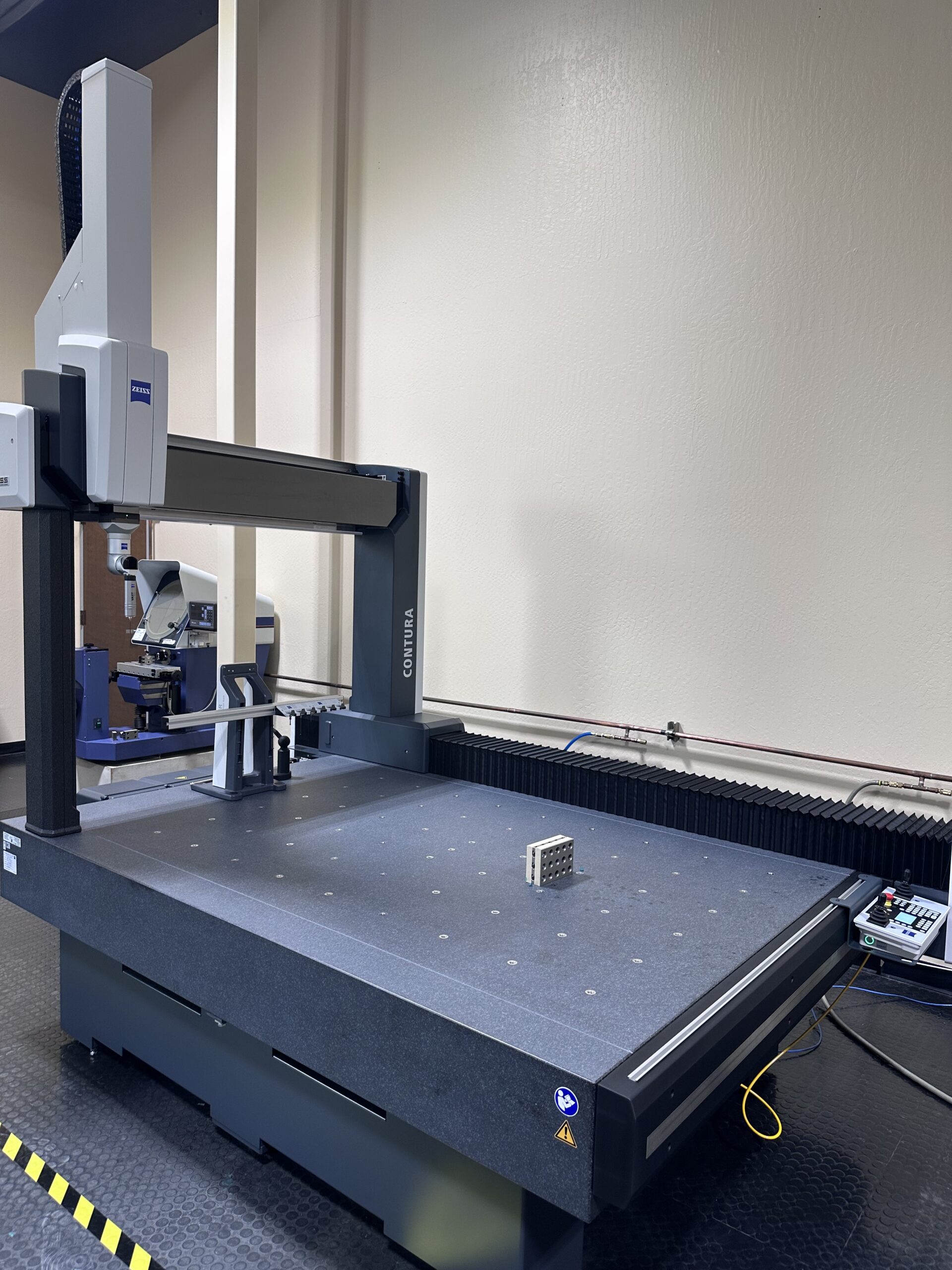

At O&Y Precision, we pride ourselves on delivering high-quality machined components with unparalleled accuracy. As part of our commitment to precision and reliability, we have recently integrated a Zeiss CMM (Coordinate Measuring Machine) into our inspection department. This advanced system ensures the highest standards in dimensional accuracy, giving our customers confidence in the quality of their parts.

What is a Zeiss CMM?

Zeiss is a globally recognized leader in metrology solutions, known for precision, reliability, and cutting-edge technology. A Coordinate Measuring Machine (CMM) is an essential tool in modern manufacturing, enabling highly accurate measurement of machined parts. Our Zeiss CMM utilizes advanced sensors and software to provide precise 3D measurement data, ensuring every component meets the tightest tolerances.

Why Zeiss?

Not all CMMs are created equal. Zeiss has built a reputation for innovation and accuracy, making it the preferred choice for industries that demand exacting standards, such as aerospace, medical, and automotive manufacturing. Here’s why we chose Zeiss:

- Unmatched Precision: High-resolution scanning probes capable of measuring parts with sub-micron accuracy.

- Advanced Software Integration: The Zeiss Calypso software allows for easy programming, automated measurement routines, and detailed reporting.

- Reliability and Durability: Engineered for long-term performance, ensuring consistent accuracy over time.

- Versatility: Ideal for measuring complex geometries and 5-axis machined parts, which are our specialty at O&Y Precision.

The Role of Quality Inspection in Precision Machining

Quality inspection is not just an afterthought—it’s an integral part of the manufacturing process. A reliable CMM is essential for:

- Ensuring Compliance: Meeting GD&T (Geometric Dimensioning and Tolerancing) standards and customer/regulatory requirements.

- Reducing Rework and Scrap: Detecting dimensional errors early minimizes costly rework and material waste.

- Improving Efficiency: Automated measurement routines enable faster and more consistent inspections, reducing downtime and increasing throughput.

- Enhancing Customer Trust: Providing detailed measurement reports showcases our commitment to quality and builds customer confidence.

How Our Zeiss CMM Benefits Our Customers

With the integration of our Zeiss CMM, O&Y Precision now offers:

- Comprehensive Inspection Reports: Providing detailed CMM reports for every part we manufacture, ensuring transparency and reliability.

- Higher Precision for Complex Parts: Whether for aerospace components, medical devices, or intricate machined parts, our Zeiss CMM guarantees top-tier accuracy.

- Faster Turnaround Times: Automated inspection processes speed up part validation, leading to reduced lead times for our customers.

Conclusion

Investing in a Zeiss CMM marks a significant step forward in our commitment to quality at O&Y Precision. By integrating this state-of-the-art technology into our workflow, we ensure every component meets the highest standards of accuracy and reliability.

It doesn’t matter if you have the machine to make the part—if you can’t check it, how do you know you’re making it to the right dimensions? Quality inspection is just as critical as machining itself, and our Zeiss CMM guarantees that every part meets precise specifications before leaving our facility.

If you’re looking for a machining partner that prioritizes quality at every step, contact us today to learn more about our capabilities and how our Zeiss CMM ensures the accuracy of your parts.

📞 Contact O&Y Precision at (robbie@oyprecision.com) or visit www.oyprecision.com to learn more.